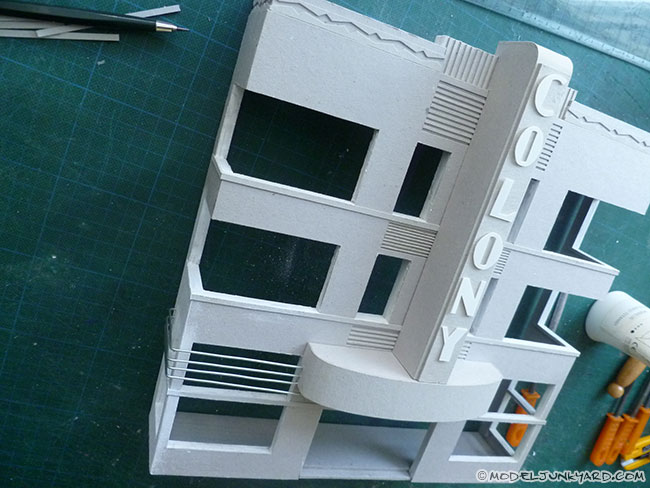

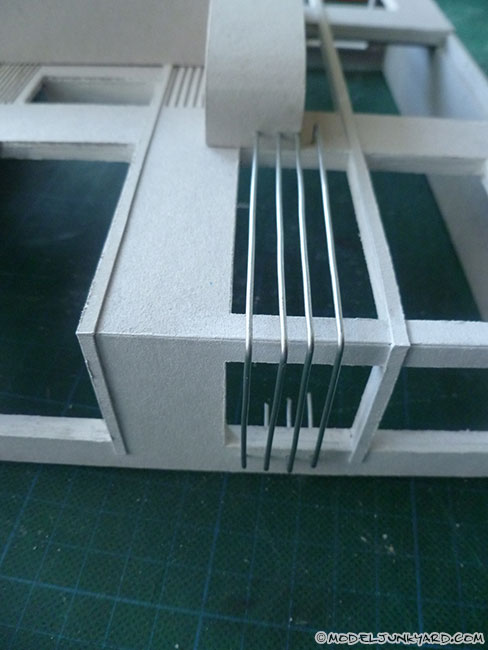

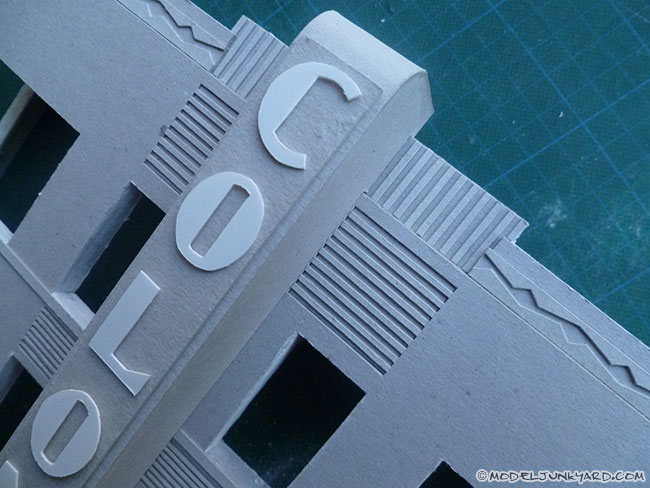

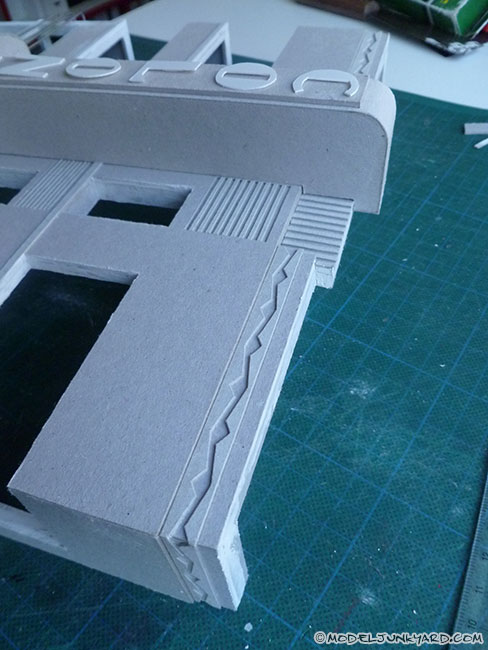

Here is the second step of this facade project. Here you can see the process of making many facade details such as cornice, moldings and windows. I used 1 and 2 mm thick grey cardboard for the facade and styrene profiles for the windows.

As always, here you have video and pics of the process.

VIDEO

PICS

Great stuff as always! You are a master of the miniature!

Have you ever given any thought to using a silhouette Cameo personal cutter? It may be able to reduce some of the hand work when cutting the larger parts. I don’t know how it would do on the little bits but it’s supposed to be able to cut chip board and styrene ??? I’d bet if you showed them your work and blog they would be happy to let you “review” one of their cutters. It seems like it would be a natural fit for both parties. “Win-Win” as they say. If it works out, just cut an extra of everything and send it to me to “review”!

Hi Nicoz, thank for the feedback. As far as I know the Cameo cutter cuts very think materials. Ford this model I use 2mm thick cardboard. I could also use 1mm thick cardboard for the facade but I think that’s also too thick for the cameo cutter, isn’t it?

Seb,

I forgot to mention that I have also seen modelers using the cameo to cut a stencil of building side wall. Say brick or block and use different types of spackling or caulking to textured panels. Sort of like a screening proccess if you follow what I mean. They look great. It may be useful for stucco style architecture????

… Once again astounding work!

Hi Nick, thanks a lot!

Seb,

I’m sorry I overlooked your reply. The info I have on it is this;

Styrene

.010 styrene sp 5 th 30 blade 6 double cut – cuts cleanly

.020 styrene sp 1 th 33 blade 10 double cut – score and snap – I ran it through the cutting process twice but I’m not sure if that’s necessary

.030 styrene sp 1 th 33 blade 10 double cut – score and snap

Card

110lb card sp 3 th 33 blade 3

Canadian Post Shredded Wheat standard size cereal box – sp 5 th 33 blade 8 double cut

Canadian Kellogs Cornflake Jumbo sized cereal box* – won’t cut through even on the settings for the thickest card, would have to finish with a knife

matt card (for matting pictures) 1.3mm thick – sp 1 thickness 33 blade 10 deep scoring, double cut – must finish with a craft knife

Seb,

sorry those are the cutter settings for the machine. Blade depth, cut speed etc.

Man, I absolutely love watching your videos and looking at your pics of you dios and all. I mostly build NASCAR and other cars and trucks. I have never done a dio but I want to try one some day. Keep up the great work and I cant wait to see the other stuff you do.